Consistent production from development to assembly is carried out in our company. The entire production of the edgewise coils field pole is at a higher level

We have equipped all the facilities for integration production from manufacture to assembly.

Further, we have winding machines of various sizes so that we can respond to the manufacture of different products for every order, such as quantity and design.

Moreover, we can deliver products of higher quality in a short lead time. Our company has installed an automatic winding machine for edgewise coil, and we aim to achieve further growth and enhance the new technology and equipment at all times.

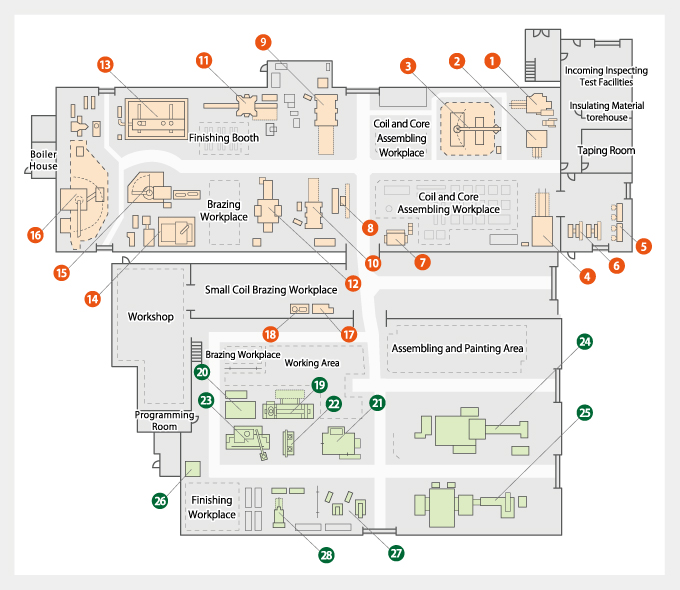

▪Map

Coil Factory

- 1400 T X 100T Two Direction Forming Press

- 2Turn Insulation Curing Press

- 3Medium Size Automatic Winding Machine

- 4Large-sized Electric Baking Oven

- 5Small-size Edgewise Winding Machine

- 6Flatwise Windind Machine

- 7High Frequency Induction Testing Machine

- 8Automatic Reversing Device

- 91200T Hydraulic Press for Turn Insulation Curing

- 10700T Hydraulic Press for Turn Insulation Curing

- 11200T Forming Press for Rotor Coil

- 12350T-150T Forming Press for Rotor Coil

- 13Large-sized Annealing Furnace

- 14Small-size Annealing Furnace

- 15Medium-size Winding Machine

- 16Large-sized Automatic Winding Machine

- 17Carbon Heater

- 18Spot Welder

Core Factory

- 19Horizontal Press for Core Assembling

- 20Damper Bar Automatic Fixing Equipment

- 21Horizontal Machining Center

- 22Band Saw

- 23Vertical Machining Center

- 24500T Crank Press with NC Feeder

- 25300T Crank Press with NC Feeder

- 26Dryer

- 27Spot Welder

- 28Vertical Press for Core Assembling

▪Crane equipment

- Coil Factory2.8t x 3 set

- Core Factory4.8t x 1 set 2.8t x 3 set