Without equipment, products cannot be made. Without technology, making a product cannot be continued for a longtime.

Without equipment, products cannot be made. Without technology, making a product cannot be continued for a longtime.

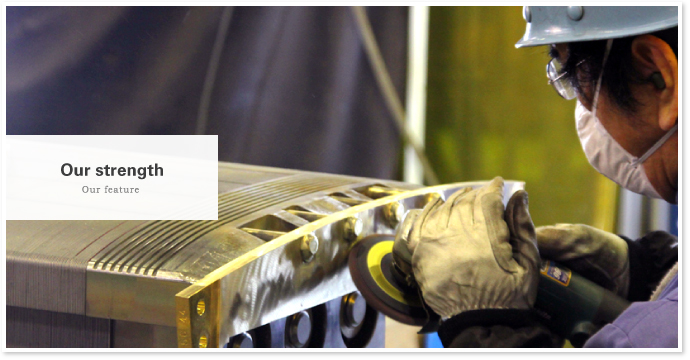

Mitani Goukin uses precise equipment and technology necessary for the production of core and coils for heavy industrial electric motors and generators.

Production facilities and dedicated expertise are essential for manufacturing large-sized coils and core. Our company is one of the leading manufacturers in Japan possessing the proper equipment and technology required for the production of large-sized coil and core.

Moreover, our qualitative products do not allow any compromise and they are highly appreciated by the customers. We have been delivering our products to heavy electrical equipment makers in Japan for many years.

- Large-sized winding machine

- The largest winding machine at our company is proud to be the largest in the country. It is essential to make edgewise coils for extra-large-sized electric motors and generators.

- Medium-size edgewise winding machine (fully automatic)

- It is a state-of-the-art winding machine (full automatic) to produce medium size edgewise coils that were included in 2013. This medium size winding machine is suitable for the winding of a coil with thin electric wire thickness, which is difficult to be done by a large-sized winding machine. It is also possible to perform speedy winding.

- Medium-size edgewise winding machine (semi-automatic)

- Although two workers are needed to operate the machine (semi-automatic) for medium size edgewise coils, the ratio of the width and thickness (W/t) of the wire is also available as large. Winding of the maximum outer diameter of about 2000×600 is possible.

Instead of simply making a coil or core, reliable quality is realized by performing compatible assembling.

Instead of simply making a coil or core, reliable quality is realized by performing compatible assembling.

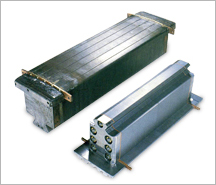

It is also possible to assemble and deliver a field pole of higher quality by conducting balanced coil and core manufacturing.

Once your order is received, we will perform the manufacturing work.

The manufactured product can be assembled in the same factory. The operation environment and insulated environment of a magnetic field system pole can be improved to the maximum quality of a coil and core by providing in the state in which it is completed as a magnetic field pole.

- The process of assembling the coil and core.

- A coil is hung with a crane, and it is put into a core and assembled.There are 7 cranes in the factory. It supports a maximum load of 4.8t.

- The process of insulated processing

of an edgewise coil. - Our highly competent staff members manage the insulating process. We have confidence in achieving speedy and quality results.

We are pleased to respond to your order quickly regardless of different designs or small quantity orders.

We are pleased to respond to your order quickly regardless of different designs or small quantity orders.

In most cases, the quantities of the coils that are currently produced by Mitani differ in terms of design for every order. Each order is responded flexibly and swiftly.

We support the production of different products from large-size coils for electric motors and generators to small coils for industrial equipment using the insulating sheathed wires.

We also handle orders of mass production flexibly as well as small lot orders such as one-piece units. In addition, we can also start quick work unique to small and medium-sized enterprises.

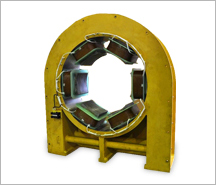

- Exciter (stator assembly)

- Field pole for hydro-power generation

- Core